Supervisors: Gediminas Račiukaitis (FTMC) & Laura Corner (University of Liverpool)

FTMC – Center for Physical Sciences and Technology is the largest research institution in Lithuania, with more than 650 employees, located in Vilnius. The Department of Laser Technologies focuses its research focuses on optical coating technologies, solid-state and fibre laser development and material processing technologies utilising ultrashort pulse lasers. Combining various processing techniques, we can shape materials with a complex design.

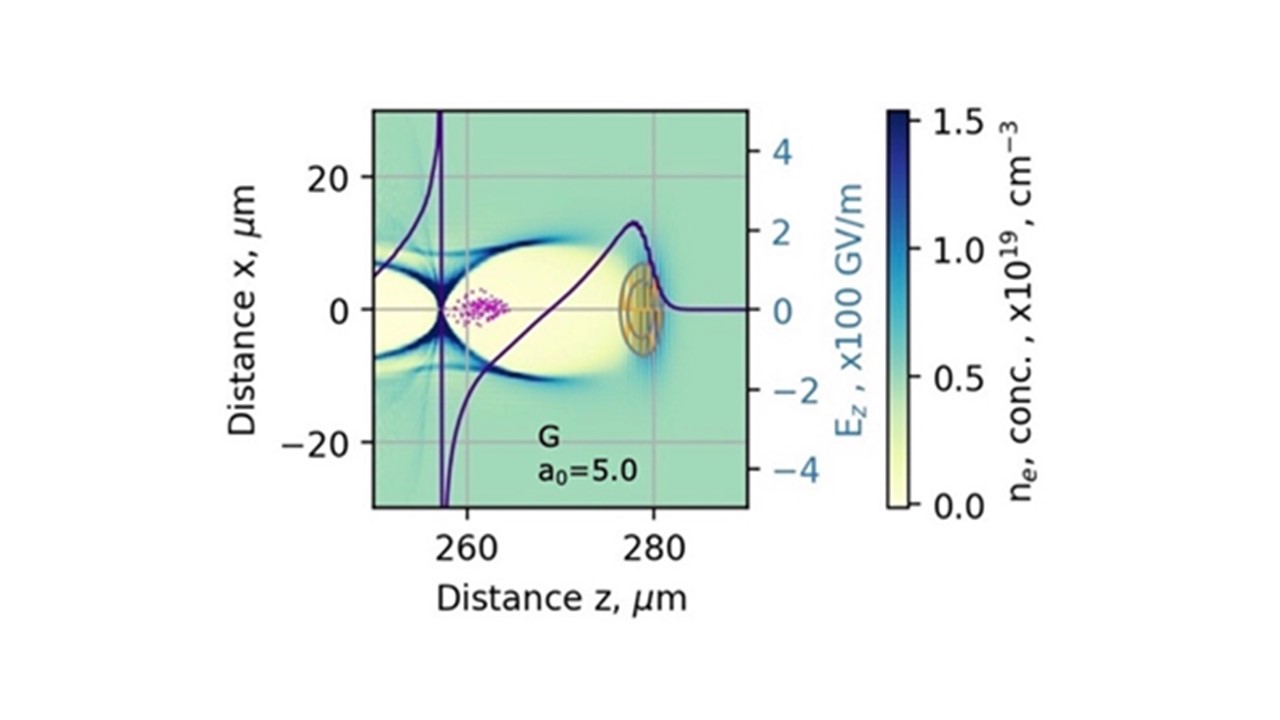

One output of that activity are components made of fused silica – nozzles for gas jets, we tailor for laser wake field acceleration (LWFA). Under intensive laser irradiation gas in the jet is ionised, providing plasma target. Laser wakefield accelerators offer a compact solution for the production of for Very High Energy Electron (VHEE) beams, which have ultra-short pulse duration with a high instantaneous dose rate and are desired for radiotherapy. Even TW-class laser pulses generate plasma wakes, which accelerate electrons to high energies in a very short distance. However, precise tailoring of the plasma profile has a considerable impact on the performance of the plasma accelerator in terms of energy efficiency, stability and durability.

Tailoring the profile of the plasma target is a delicate job. We utilise a combined laser micromachining technology with short-pulse and ultra-short-pulse lasers to manufacture complex gas nozzles in fused silica. The process includes mechanical design of the nozzles, fluid simulations with ANSYS Fluent, optical simulation of the laser beam shaping and Fourier-Bessel Particle-In-Cell (FBPIC) simulation of electron acceleration and a plasma wake, generated inside the plasma target before the real manufacturing. Multiple loops of optimisation should be run to select the most efficient solution. 3D characterisation of gas jets and plasma target are performed before experimental implementation of electron acceleration and related processes with TW and PW class lasers at the partner facilities in Europe and worldwide.

Expected Results

- Develop and characterise a series of plasma targets using hybrid laser microfabrication technology

- Quantification of nozzle performance at project partner facilities (CNRS (LOA), ULUND) and/or ELI-ALPS with the SYLOS3 laser (alternative ELI Beamlines ALLEGRO laser)

Planned secondments

- 4 months at University of Liverpool (year 1): investigate gas jet stability

- 4 months at University of Liverpool (year 2): compare developed nozzle with existing

- 1 months at ELI-ALPS (year 3): install developed nozzles and SYLOS 3 laser on LWFA

- 2 weeks at Lund University (year 3): install developed nozzles toward LFWA for VHEE